Magazine: Profile

Josh Vekhter

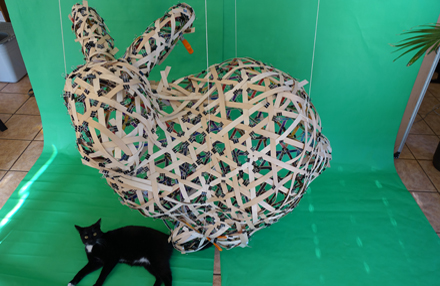

from foolish products to basket weaving

Josh Vekhter

from foolish products to basket weaving

Full text also available in the ACM Digital Library as PDF | HTML | Digital Edition

Thank you for your interest in this article. This content is protected. You may log in with your ACM account or subscribe to access the full text.